Professor, Acting Head

Chemical Engineering, Faculty

robin.hutchinson@queensu.ca

Phone: 613-533-3097

Fax: 613-533-6637

Dupuis Hall, Room: Room 426

Our process development/modeling efforts are only possible with knowledge of the underlying polymerization mechanisms and accurate values of kinetic rate coefficients. Thus, many of our projects include the study of polymerization kinetics using the PLP/MMD technique, in which pulsed-laser polymerization (PLP) is combined with analysis of the resulting polymer molar mass distribution (MMD) to directly estimate kp, the chain growth rate coefficient for radical polymerization.

Dr. Hutchinson is a pioneer in the development and application of PLP, leading a program to utilize the new technique to measure kp values for many monomers of industrial interest while at DuPont (1991-2000). He is currently co-chair of the IUPAC (Polymer Division) subcommittee on Polymerization Mechanisms and Kinetics, and has on-going collaborations regarding the analysis and interpretation of PLP/MMD experimentation with Dr. Anatoly Nikitin. The laser setup at Queen's is the only one of its kind in North America. Our laser for PLP/MMD studies was purchased in 2013 thanks to an NSERC "Research Tools and Instrumentation" grant, and sees continuous use supporting a range of recent and ongoing projects, including the ongoing investigation of radical copolymerization kinetics in aqueous vs organic solution and in alcohol/water mixtures (Ibrahim Refai and Maryam Agboluaje, sponsored by NSERC and BASF)

Findings from the PLP/MMD technique are often combined with NMR measurements of copolymer composition or branching levels to develop new mechanistic insights regarding hydrogen-bonding effects on polymerization kinetics, copolymerization penultimate effects, and acrylate side-reactions. In addition, we continue to study new monomer systems to support development of new materials.

Recent Publications

Hutchinson, R. A., S. Beuermann, "Critically Evaluated Propagation Rate Coefficients for Radical Polymerization: Acrylates and Vinyl Acetate (IUPAC Technical Report)", Pure Appl. Chem. 91, 1883-1888, 2019 [More information].

Idowu, L. A., R. A. Hutchinson, "Solvent Effects on Radical Copolymerization Kinetics of 2-Hydroxyethyl Methacrylate and Butyl Methacrylate", Polymers 11, 487, 2019 [More information].

Nikitin, A. N., I. Lacík, R. A. Hutchinson, M. Buback, G. T. Russell, “Detection of PLP Structure for Accurate Determination of Propagation Rate Coefficients over an Enhanced Range of PLP-SEC Conditions”, Macromolecules 52, 55-71, 2019 [More information].

Rooney, T. R., A. Chovancová, I. Lacík, R. A. Hutchinson, "Pulsed Laser Studies of Cationic Reactive Surfactant Propagation Kinetics", Polymer 130, 39-49, 2017 [More information]

Schier, J. E. S., D. Cohen-Sacal, R. A. Hutchinson, "Hydrogen Bonding in Radical Solution Copolymerization Kinetics of Acrylates and Methacrylates: A Comparison of Hydroxy- and Methoxy- Functionality", Polym. Chem. 8, 1943-1952, 2017 [More information].

Rooney, T. R., D. Moscatelli, R. A. Hutchinson, “Polylactic Acid Macromonomer Radical Propagation Kinetics and Degradation Behaviour”, React. Chem. Eng. 2, 487-497, 2017 [More information]

Past Graduate Students who have used the PLP/MMD technique in their research

Loretta Idowu (MSc, 2016-2019) "Radical Copolymerization Kinetics and Functional Group Distribution of Hydroxyl-Containing Copolymers"

Sharmaine Luk (MSc, 2015-2017) "Radical Polymerization Kinetics of Bio-renewable Butyrolactone Monomers in Aqueous Solution"

Jan Schier (PhD, 2013-2017) "Hydrogen Bonding in Radical Copolymerization: A Kinetic Investigation under Industrially Relevant Conditions"

Thomas Rooney (PhD, 2012-2017) "Synthesis, Polymerization Kinetics and Applications of Novel Macromonomer-Based Degradable Materials"

Otlaatla Monyatsi (MSc, 2013-2015) "Radical Polymerization Studies of Vinyl Ester Monomers using Pulsed‐Lased Polymerization with Size Exclusion Chromatography (PLP‐SEC)"

Kun Liang (PhD, 2009-2013) "Free-Radical Copolymerization of Hydroxy-functional Monomers: Kinetic and Semibatch Studies"

Robert Cockburn (MSc, 2009-2011) "Kinetics, Synthesis and Characterization of Copolymers Containing the Bio-Renewable Monomer g-Methyl-a-Methylene-g-Butyrolactone"

Wei Wang (PhD, 2006-2010) "A Comprehensive Kinetic Model for High Temperature Free Radical Production of Styrene/Methacrylate/Acrylate Resins"

Siziwe Bebe (PhD, 2002-2008) "Estimation of Free Radical Polymerization Rate Coefficients using Computational Chemistry"

Ning Li (MSc, 2003-2005) "Investigation of Free Radical Polymerization Propagation Kinetics by Pulsed-Laser Polymerization"

Deheng Li (MSc, PhD, 2001-2006) "Modeling of Kinetic Complexities in High Temperature Free Radical Terpolymerization for Production of Acrylic Coatings Resins"

In addition, the equipment has been used for a number of undergraduate thesis projects supporting research efforts in the Hutchinson group.

Water-soluble polymers are used for a wide range of applications in the cosmetics, pharmaceutical, water treatment, and coatings industries. Funded by BASF (Germany), we work closely with the research groups of Professor Michael Buback (University of Göttingen, Germany) and Professor Igor Lacík (Polymer Institute of the Slovak Academy of Sciences, Bratislava, Slovakia), who are applying pulsed-laser techniques to the study of polymerization kinetics in water. They have shown that the propagation kinetics of these monomers vary with concentration and conversion when polymerized in the aqueous phase, a behavior not seen for polymerization in organic solvents. In addition, the formation and consumption of midchain radicals affects aqueous phase (co)polymerization rates of acrylic acid and acrylamide.

Based on this new understanding, the Hutchinson group has developed computer models for the batch and semibatch aqueous-phase homo and copolymerization of a range of systems, verified against experiments conducted in the laboratory. The studies not only supply information useful for industrial process and product development of these environmentally-friendly polymerization systems, they also provide unique insight to the effect of solvent on radical polymerization kinetics. PhD student Maryam Agboluaje is currently investigating acrylate-acrylamide copolymerization kinetics in alcohol/water mixtures experimentally using an in-situ NMR technique, with the results providing the understanding needed to develop a detailed mechanistic model of the system. The effort is supported by a PLP/MMD study conducted by Ibrahim Refai, and a semi-batch radical polymerization investigation by Gagandeep Kaur.

Recently graduated PhD student Ikenna Ezenwajiaku developed models to represent the complex copolymerization kinetics of cationic monomers with acrylic acid, following the previous efforts of Calista Preusser who studied the copolymerization of acrylic acid and acrylamide as a function of monomer concentration and system pH. Key to the studies is experimental determination of comonomer composition drift using an in-situ NMR technique.

Ezenwajiaku, E. H., R. Zigelstein, A. Chovancová, I. Lacík, R. A. Hutchinson, "Experimental and Modeling Investigation of Aqueous-Phase Radical Copolymerization of 2-(Methacryloyloxyethyl)trimethylammonium Chloride with Acrylic Acid", Ind. Eng. Chem. Res. 59, 3359-3374, 2020 [More information].

Ezenwajiaku, E. H., A. Chovancová, K. C. Lister, I. Lacík, R. A. Hutchinson, "Experimental and Modeling Investigation of Radical Homopolymerization of 2-(Methacryloyloxyethyl) Trimethylammonium Chloride in Aqueous Solution", Macromol. React. Eng. 14, 201900033, 2020 [More information].

Preusser, C., A. Chornocová, I. Lacík, R. A. Hutchinson, "Modeling The Radical Batch Polymerization of Acrylamide in Aqueous Solution", Macromol. React. Eng. 10, 490-501, 2016 [More information].

Preusser, C., R. A. Hutchinson, "Measuring and Modeling The Peculiarities of Aqueous-Phase Radical Polymerization", Can. J. Chem. Eng. 94, 2045-2051, 2016 [More information].

Preusser, C., I. H. Ezenwajiaku, R. A. Hutchinson, "The Combined Influence of Monomer Concentration and Ionization on Acrylamide/Acrylic Acid Composition in Aqueous Solution Radical Batch Copolymerization", Macromolecules 49, 4746-4756, 2016 [More information].

Wittenberg, N. F. G., C. Preusser, H. Kattner, M. Stach, I. Lacík, R. A. Hutchinson, M. Buback, "Modeling Acrylic Acid Radical Polymerization in Aqueous Solution," Macromol. React. Eng. 10, 95-107, 2016 [More information].

Past Graduate Students

Ikenna Ezenwajiaku (PhD, 2015-2020) "Kinetics and Modeling of Radical Copolymerization of Water-Soluble Cationic Monomers"

Calista Preusser (PhD, 2010-2015) "Kinetics and Modeling of Free Radical Aqueous‐Phase Polymerization of Acrylamide with Acrylic Acid at Varying Degrees of Ionization"

Sandhya Santanakrishnan (PhD, 2007-2011) "Kinetic Modeling of Homo- and Co- Polymerization of Water-Soluble N-Vinyl Monomers"

Inga Utz (MSc, 2007-2008) "Modeling of Aqueous-Phase Free-Radical Polymerization Kinetics"

Lina Tang (2004-2007) "Free Radical Polymerization Kinetics of N-Vinyl Pyrrolidone in Aqueous Solution"

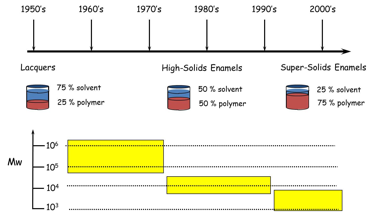

The manufacture of synthetic polymers produced via radical polymerization is energy intensive and often utilizes solvents to control system viscosity or for heat removal. This strong impetus to reduce the environmental footprint has led to a shift in the process technology used to produce the polymer component of most automotive clearcoats. Currently, low molar mass polymer chains are produced with low solvent content; these chains form a polymer network on the surface to be coated via reaction of the functional groups with an added cross-linking agent. Sufficient functional monomer (e.g., hydroxyethyl acrylate, glycidyl methacrylate) must be included in the resin recipe to ensure that close to 100% of the chains participate in the cross-linking reactions.

The manufacture of synthetic polymers produced via radical polymerization is energy intensive and often utilizes solvents to control system viscosity or for heat removal. This strong impetus to reduce the environmental footprint has led to a shift in the process technology used to produce the polymer component of most automotive clearcoats. Currently, low molar mass polymer chains are produced with low solvent content; these chains form a polymer network on the surface to be coated via reaction of the functional groups with an added cross-linking agent. Sufficient functional monomer (e.g., hydroxyethyl acrylate, glycidyl methacrylate) must be included in the resin recipe to ensure that close to 100% of the chains participate in the cross-linking reactions.

Secondary reactions have a marked effect on rate and polymer structure under the polymerization conditions used industrially. The Hutchinson group has studied the mechanisms and constructed models to represent how methacrylate depropagation, acrylate branching and scission, and penultimate chain-growth copolymerization kinetics control reaction rate and polymer molecular weight during high-temperature acrylate/methacrylate, styrene/methacrylate, and styrene/acrylate copolymerization. The improved understanding is captured in models used to improve manufacturing practices and reduce the effort required to develop new coatings resins. Recent efforts have extended the studies to include hydroxyfunctional monomers, the development of kinetic Monte-Carlo techniques to model the distribution of functionality among the low-MW polymer chains, and the optimization of semi-batch operating strategies to improve both product uniformity and process efficiency. This research has been funded continuously by Axalta Coating Systems (formerly DuPont Performance Coatings) since 2001, with matching funds obtained at times through NSERC.

Current and recent projects in this area include:

|

|

|

The 1 L automated reactor system used to investigate |

Recent publications

Nasresfahani, A., R. A. Hutchinson, "Deterministic Approach to Estimate Functionality of Chains Produced by Radical Copolymerization in the Presence of Secondary Reactions", Macromolecules 53, 5674-5686, 2020 [More Information].

Heidarzadeh, N., R. A. Hutchinson, "Maximizing Macromonomer Content Produced by Starved-Feed High Temperature Acrylate/Methacrylate Semi-Batch Polymerization", Polym. Chem. 11, 2137-2146, 2020 [more information]

Idowu, L. A., R. A. Hutchinson, "Solvent Effects on Radical Copolymerization Kinetics of 2-Hydroxyethyl Methacrylate and Butyl Methacrylate", Polymers 11, 487, 2019 [More information].

Nasresfahani, A., L. A. Idowu, R. A. Hutchinson, "Extractable Content of Functional Acrylic Resins Produced by Radical Copolymerization: A Comparison of Experiment and Stochastic Simulation", Chem. Eng. J. 378, 122087, 2019 [More Information].

Schier, J. E. S., M. Zhang, M. C. Grady, R. A. Hutchinson, “Modeling of Semi-batch Solution Radical Copolymerization of Butyl Methacrylate and 2-Hydroxyethyl Acrylate”, Macromol. React. Eng. 12, 1800008, 2018 [More information].

Zhang, M., R. A. Hutchinson, “Synthesis and Utilization of Low Dispersity Acrylic Macromonomer as Dispersant for Nonaqueous Dispersion Polymerization”, Macromolecules 51, 6267-6275, 2018 [More information].

Nasresfahani, A., R. A. Hutchinson, “Modeling the Distribution of Functional Groups in Semibatch Radical Copolymerization: An Accelerated Stochastic Approach”, Ind. Eng. Chem. Res. 57, 9407-9419, 2018 [More information].

Zhang, M., R. A. Hutchinson, “Design of Acrylic Dispersants for Nonaqueous Dispersion Polymerization: The Importance of Thermodynamics”, Macromol. React. Eng. 12, 1800025, 2018 [More information].

Past graduate students (sponsored by Axalta Coating Systems, Dupont and NSERC, unless otherwise noted)

Amin Nasrefsahani (PhD, 2017-2020) "Acclerated Monte-Carlo Techniques for Modeling of Chain Architecture and Semi-batch Radical Polymerization Process Optimization"

Loretta Idowu (MSc, 2016-2019) "Radical Copolymerization Kinetics and Functional Group Distribution of Hydroxyl-Containing Copolymers"

Mingmin Zhang (PhD, 2015-2018) "Design and Synthesis of Acrylic Dispersants for Nonaqueous Dispersion Polymerization"

Jan Schier (PhD, 2013-2017) "Hydrogen Bonding in Radical Copolymerization: A Kinetic Investigation under Industrially Relevant Conditions"

Weiwei Yang (PhD, 2011-2016) "Non‐Aqueous Dispersion Polymerization for Automotive Coating Applications"

M. Ali Parsa (MSc, 2012-2014) "Combined Monte‐Carlo and Deterministic Modeling Techniques applied to Polymerization Systems"

Kun Liang (PhD, 2009-2013) "Free-Radical Copolymerization of Hydroxy-functional Monomers: Kinetic and Semibatch Studies"

Raul Moraes (PhD, 2007-2011) "Pushing the Boundaries of Concentrated Dispersions: High Solids Content Bimodal Latex for Paper Coating Applications" (sponsored by BASF)

Wei Wang (PhD, 2006-2010) "A Comprehensive Kinetic Model for High Temperature Free Radical Production of Styrene/Methacrylate/Acrylate Resins"

Onyinye Okorafo (MSc, 2007-2009) "On-Line Optimization for a Batch-Fed Copolymerization Reactor with Partial State Measurement"

Luis Fernando Perea (MSc, 2005-2007) "Optimization and Control of Semibatch Free Radical Copolymerization"

Deheng Li (MSc, PhD, 2001-2006) "Modeling of Kinetic Complexities in High Temperature Free Radical Terpolymerization for Production of Acrylic Coatings Resins"

Adam Peck (MSc, 2001-2003) "Investigation of Free Radical Polymerization Propagation Kinetics by Pulsed-Laser Polymerization"

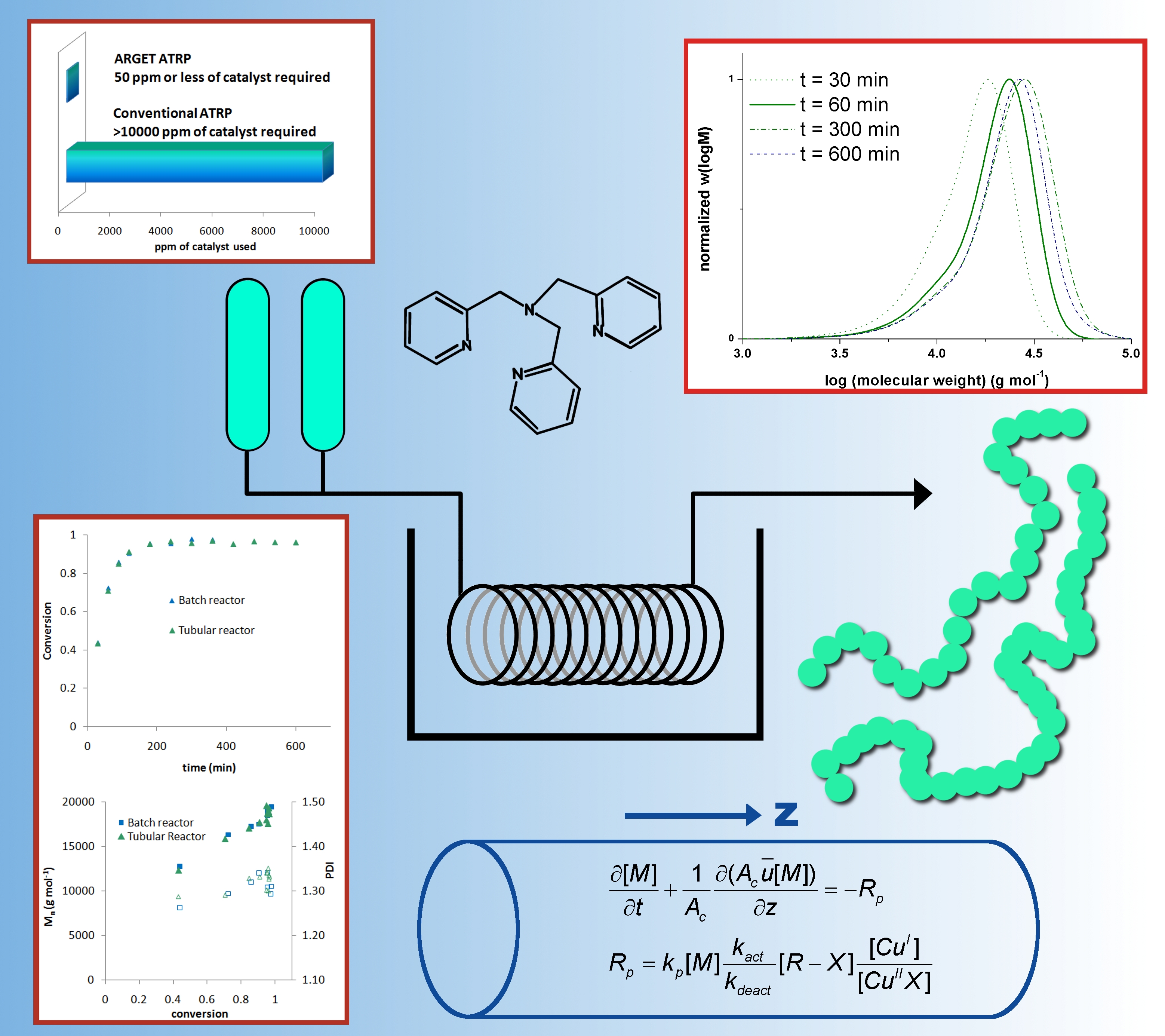

An ongoing program explores the industrial application controlled radical polymerization (CRP) to produce polymers with narrow molar mass distribution and controlled structure. In particular, the group has studied the application of Cu-catalyzed systems known collectively as Atom Transfer Radical Polymerization (ATRP). The technique has great promise, but several factors must be overcome (residual Cu catalyst concentration; expensive reagents; lower polymerization rate) before it is industrially viable. The group has constructed tubular and well-mixed reactor systems for continuous production of polymer with controlled chain lengths at ppm levels of Cu catalyst at reaction rates that approach those of conventional free radical polymerization. Current process development focuses on Cu(0)-mediated production of poly(acrylate) macroinitiators in a tubular reactor, followed by chain-extension to produce block copolymers in a semi-batch process.

Current and recent projects in this area include:

Key Publications

Shirali Zadeh, N., M. J. Cooze, N. R. Barr, R. A. Hutchinson, "An Efficient Process for the Cu(0)-mediated Synthesis and Subsequent Chain Extension of Poly(methyl acrylate) Macroinitiator", React. Chem. Eng. 4, 2000-2010, 2019 [More Information]

Zhang, M., R. A. Hutchinson, “Modeling the Synthesis of Butyl Methacrylate Macromonomer by Sequential ATRP-CCTP”, Macromol. React. Eng. 13, 1800062, 2019 [More information].

Zhang, M., R. A. Hutchinson, “Synthesis and Utilization of Low Dispersity Acrylic Macromonomer as Dispersant for Nonaqueous Dispersion Polymerization”, Macromolecules 51, 6267-6275, 2018 [More information].

Payne, K. A., J. Debling, P. Nesvadba, M. F. Cunningham R. A. Hutchinson, "NMP of styrene in batch and CSTR at elevated temperatures: Modeling experimental trends", Eur. Polym. J. 80, 186-199, 2016 [More information].

Zhang, M., M. F. Cunningham R. A. Hutchinson, "Aqueous Copper(0) Mediated Reversible Deactivation Radical Polymerization of 2-Hydroxyethyl Acrylate," Polym. Chem. 6, 6509-6518, 2015 [More information].

Payne, K. A., P. Nesvadba, J. Debling, M. F. Cunningham R. A. Hutchinson, "Nitroxide-Mediated Polymerization at Elevated Temperatures," ACS Macro Lett. 4, 280-283, 2015 [More information].

Payne, K. A., D. R. D'hooge, P. H. M. Van Steenberge, M.-F. Reyniers, M. F. Cunningham, R. A. Hutchinson, G. B. Marin, "ARGET ATRP of Butyl Methacrylate: Utilizing Kinetic Modeling to Understand Experimental Trends," Macromolecules 46, 3828-3840, 2013 [More information].

Chan, N., M. F. Cunningham, R. A. Hutchinson, "Copper Mediated Controlled Radical Polymerization in Continuous Flow Processes: Synergy between Polymer Reaction Engineering and Innovative Chemistry," J. Polym. Sci., Part A: Polym. Chem. 51, 3081-3096, 2013 [More information]. Invited Highlight.

Past graduate students (sponsored by NSERC, unless otherwise noted)

Niloofar Shirali Zadeh (MSc, 2017-2019) "An Efficient Process for the Cu(0)-mediated Synthesis and Subsequent Chain Extension of Poly(methyl acrylate) Macroinitiator" (sponsored by Nipsea Technologies)

Mingmin Zhang (PhD, 2015-2018) "Design and Synthesis of Acrylic Dispersants for Nonaqueous Dispersion Polymerization" (sponsored by Axalta Coating Systems)

Kevin Payne (PhD 2010-2015; co-supervised by M. F. Cunningham) "Controlled Radical Polymerization: Towards an Industrial Process" (sponsored by BASF and NSERC)

Mingmin Zhang (MSc 2013-2015; co-supervised by M. F. Cunningham) "Aqueous Cu(0)‐Mediated Reversible Deactivation Radical Polymerization of 2‐Hydroxyethyl Acrylate"

Nicky Chan (PhD 2006-2012; co-supervised by M. F. Cunningham) "Atom Transfer Radical Polymerization with Low Catalyst Concentration in Continuous Reactors"

Yao Fu (PhD 2002-2007, co-supervised by M. F. Cunningham) "Living Radical Polymerization Techniques applied to Semibatch Solution Polymerization"

The Hutchinson group has used their facilities and expertise in radical polymerization to develop (often collaboratively) novel processes and products.

Current and recent projects in this area are sponsored by NSERC, unless otherwise noted:

Recent publications

Heidarzadeh, N., E. G. Bygott, R. A. Hutchinson, "Exploiting Addition–Fragmentation Reactions to Produce Low Dispersity Poly(isobornyl acrylate) and Blocky Copolymers by Semibatch Radical Polymerization". Macromol. Rapid Commun. 41, in press, 2020 [more information].

Lister, K. C., H. Kaminsky, R. A. Hutchinson, "Evaluation of a Novel Polymeric Flocculant for Enhanced Water Recovery of Mature Fine Tailings", Processes 8, 735, 2020 [More information]. Invited contribution

Heidarzadeh, N., R. A. Hutchinson, "Maximizing Macromonomer Content Produced by Starved-Feed High Temperature Acrylate/Methacrylate Semi-Batch Polymerization". Polym. Chem. 11, 2137-2146, 2020 [more information].

Russell, D. A., L. Meunier, R. A. Hutchinson, "Characterization of Degradation Products from a Hydrolytically Degradable Cationic Flocculant", Polym. Degrad. Stab. 174, 109097, 2020 [More information].

Younes, G. R., A. R. Proper, T. R. Rooney, R. A. Hutchinson, S. B. Gumfekar, J. B. P. Soares, “Structure Modifications of Hydrolytically-Degradable Polymer Flocculant for Improved Water Recovery from Mature Fine Tailings”, Ind. Eng. Chem. Res. 57, 10809-10822, 2018. [More information].

Luk, S. B., R. A. Hutchinson, "Radical Copolymerization Kinetics of Bio-Renewable Butyrolactone Monomer in Aqueous Solution", Processes 5, 55, 2017 [More information].

Gumfekar, S. P., T. R. Rooney, R. A. Hutchinson, J. B. P. Soares, "Dewatering Oil Sands Tailings with Degradable Polymer Flocculants", ACS Appl. Mater. Interfaces 9, 36290-36300, 2017 [More information].

Luk, S. B., J. Kollár, A. Chovancová, M. Mrlík, I. Lacík, J. Mosnáček, R. A. Hutchinson, "Superabsorbent Hydrogels made from Bio-sourced Butyrolactone Monomer in Aqueous Solution", Polym. Chem. 8, 1943-1952, 2017 [More information].

Rooney, T. R., D. Moscatelli, R. A. Hutchinson, “Polylactic Acid Macromonomer Radical Propagation Kinetics and Degradation Behaviour”, React. Chem. Eng. 2, 487-497, 2017 [More information].

Past graduate students:

Kyle Lister (MSc, 2018-2020) "Evaluation of a Novel Polymeric Flocculant for Enhanced Water Recovery of Mature Fine Tailings"

Georges Younes (MSc, 2016-2018) "Hydrolytically Degradable Cationic Flocculants for Improved Water Recovery from Mature Fine Tailings"

Sharmaine Luk (MSc, 2015-2017) "Radical Polymerization Kinetics of Bio-renewable Butyrolactone Monomers in Aqueous Solution"

Thomas Rooney (PhD, 2012-2017) "Synthesis, Polymerization Kinetics, and Applications of Novel Macromonomer-Based Degradable Materials"

Robert Cockburn (MSc, 2009-2011) "Kinetics, Synthesis and Characterization of Copolymers Containing the Bio-Renewable Monomer g-Methyl-a-Methylene-g-Butyrolactone"

Every year finds one or two 4th year CHEE or ENCH students conducting research in the Hutchinson lab. In addition, there is the occasional opportunity to gain summer work experience under the NSERC USRA program. The projects are designed to allow the student to work independently on a topic that is related to an ongoing group research project, under the supervision of a graduate student in the lab. Contact Dr. Hutchinson if you are interested! Some of the students -- most recently Elizabeth Bygott, Morgan Cooze, Kyle Lister, Sharmaine Luk, and Otlaatla Monyatsi -- have stayed with the group as graduate students, and occasionally the undergraduate research leads to a research publication to add to your CV.

Recent publications with undergrad co-authors in bold

Heidarzadeh, N., E. G. Bygott, R. A. Hutchinson, "Exploiting Addition–Fragmentation Reactions to Produce Low Dispersity Poly(isobornyl acrylate) and Blocky Copolymers by Semibatch Radical Polymerization". Macromol. Rapid Commun. 41, 2000288, 2020 [more information].

Ezenwajiaku, E. H., R. Zigelstein, A. Chovancová, I. Lacík, R. A. Hutchinson, "Experimental and Modeling Investigation of Aqueous-Phase Radical Copolymerization of 2-(Methacryloyloxyethyl)trimethylammonium Chloride with Acrylic Acid", Ind. Eng. Chem. Res. 59, 3359-3374, 2020 [More information].

Shirali Zadeh, N., M. J. Cooze, N. R. Barr, R. A. Hutchinson, "An Efficient Process for the Cu(0)-mediated Synthesis and Subsequent Chain Extension of Poly(methyl acrylate) Macroinitiator", React. Chem. Eng. 4, 2000-2010, 2019 [More Information].

Younes, G. R., A. R. Proper, T. R. Rooney, R. A. Hutchinson, S. B. Gumfekar, J. B. P. Soares, “Structure Modifications of Hydrolytically-Degradable Polymer Flocculant for Improved Water Recovery from Mature Fine Tailings”, Ind. Eng. Chem. Res. 57, 10809-10822, 2018. [More information]

Schier, J. E. S., D. Cohen-Sacal, O. R. Larsen, R. A. Hutchinson, "The Effect of Hydrogen Bonding on Radical Semi-Batch Copolymerization of Butyl Acrylate and 2-Hydroxyethyl Acrylate", Polymers (MDPI), 9, 368-382, 2017 [More information]. Invited contribution

List of undergrad research projects (since 2013) with Course Codes

Katrina Phe (2020-21) ENCH 417

Establishing Reaction Conditions for Cu(0)-mediated Polymerization of less-reactive Monomers

Bethany Viray (2019-20) ENCH 417

Incorporation of Acid Functionality in Cu(0)-mediated Polymerization

Elizabeth Bygott (2019-20) Summer Student and CHEE 421

Optimizing Process Conditions for Production of TDB-functional poly(acrylates)

Michelle Gelber (2018-19) CHEM 497

Solvent Effects on the Propagation Kinetics of Water-Soluble Monomers

Morgan Cooze (2018-19) Summer Student and ENCH 417

Cu(0)-Mediated Production and Chain Extension of Poly(methyl acrylate) Macroinitiator

Jeremy Hsieh (2018-19) ENCH 417

Synthesis and Characterization of Cationic Copolymers in Aqueous Solution in a Semi-batch Process

Rachel Zigelstein (2018) NSERC USRA Summer Student

Characterization of Acrylic Acid/Cationic Comonomer Monomer and Polymer Aqueous Solutions

Kyle Lister (2017-18) CHEE 421

Measurement of Polyelectrolyte Properties for Improved Knowledge of Radical Copolymerization of Water-Soluble Monomers

Abbigale Proper (2017) Summer Student

The Influence of Macromonomer Structure on Flocculation of OIl Sands Tailings.

Dustin Boumeester (2016-17) ENCH 417

Solvency Effects upon Nonaqueous Dispersion Polymerization.

Erica Moran (2016-17) ENCH 417

Investigation of Semibatch Copolymerization under Reflux Conditions.

David Cohen-Sacal (2016) NSERC USRA Summer Student

The Influence of Solvent Choice on Acrylate Copolymerization Kinetics.

Arman Al Harari (2015-16) CHEE 421

Testing of Biodegradable Flocculants for theTreatment of Oil Sands Tailings.

Eric Donders (2015-16) ENCH 417

Preparation and Analysis of PVA-Encapsulated Praziquantel Nanosuspensions.

Trevor Hachie (2015-16) ENCH 417 (co-supervised by Lindsay Fitzpatrick)

Production and Investigation of Micro-scale P(MMA-co-MAA) Particles for Tissue Integration in Zebrafish Platform.

Owen Larsen (2015-16) ENCH 417

Semibatch Studies of Butyl Acrylate and 2‐Hydroxyethyl Acrylate Copolymerization.

Eric Donders (2015) NSERC USRA summer student

Application of a New Reactive Dispersant for Non-Aqueous Dispersion Polymerization.

Cameron Giglio (2014-15) ENCH 417

Synthesis and Kinetic Studies of Novel Biodegradable Lactic Acid Based Macromonomers.

Nick Volkmer (2014-15) ENCH 417

Particle Nucleation in Non-Aqueous Dispersion Polymerization.

Sharmaine Luk (2014-15) ENCH 417

Influence of Di(meth)acrylate Impurities in Hydroxy Functional Copolymerization.

Stephanie Wilburn (2013-14) NSERC USRA summer student and ENCH 417

Particle Nucleation in Non-Aqueous Dispersion Polymerization.