Dr. Vahid Fallah has over 15 years of experience in academic research and industrial R&D in the fields of Additive Manufacturing (AM), Solidification and Casting, Precipitation Hardening (of aerospace & automotive aluminum alloys), Solid-State Welding, and Computational Materials Science. Dr. Fallah earned his PhD in 2011 with a focus on laser additive manufacturing of advanced metals and metal matrix composites. From 2011 to 2015, he served as a postdoctoral fellow and research associate at McMaster University and University of Waterloo, and collaborated with Novelis Inc. on development of high-strength automotive aluminum alloys. Prior to joining Queen’s University in January 2018, as a senior scientist and technical project leader at Alcereco Inc., Dr. Fallah led several Industrial R&D projects. Among these are the successful development of superior continuously-cast Al-Sc alloys and thermomechanical processing routes for aerospace industries (sponsored by Airbus), as well as a proprietary atomization technology for specialty/spherical powders for AM applications (led to the establishment of Equispheres Inc.).

Areas of Research

Research Projects

Thin Strip Casting- Process & Material Development: In collaboration with Hazelett CastechnologyTM, we are rigorously working on the optimization of process and product performances of an state-of-the-art Strip Casting technology tailored for direct manufacturing of thin (~2mm) aluminum sheets for automotive applications.

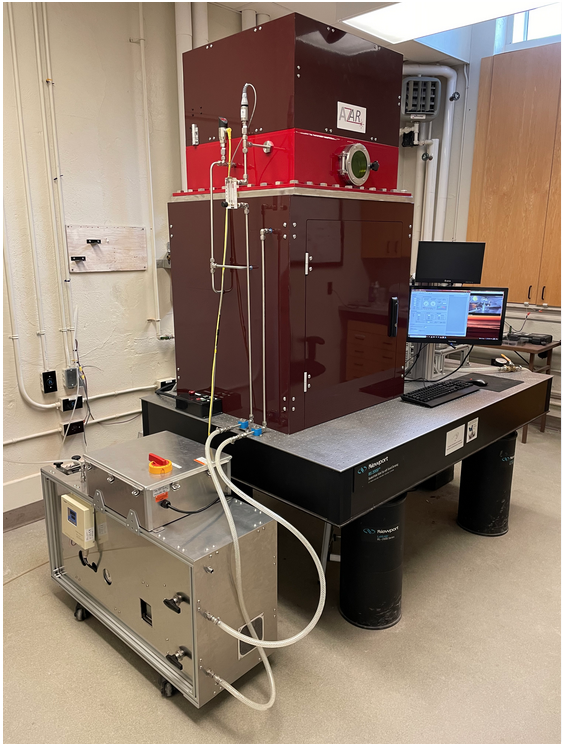

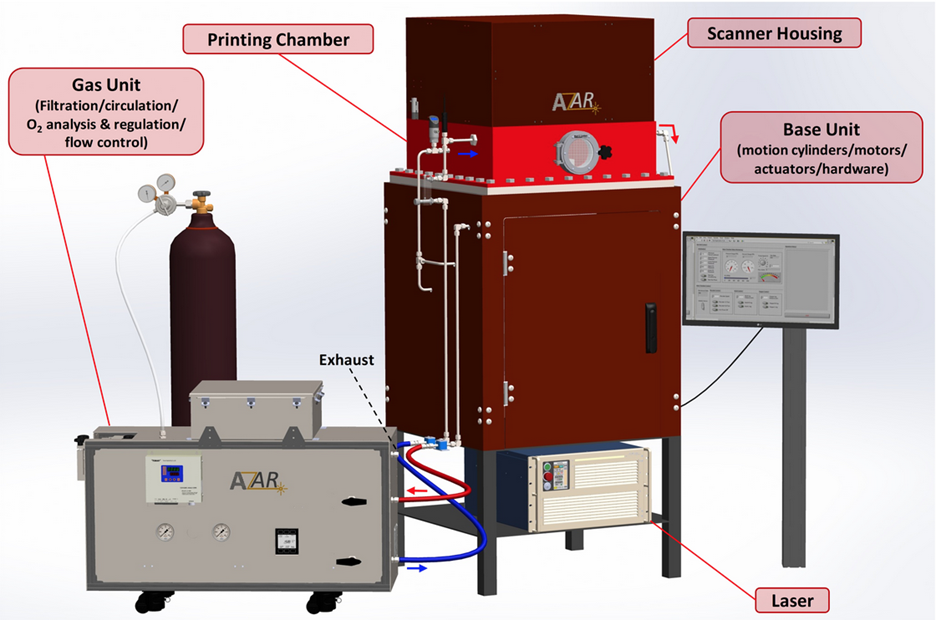

Laser Powder Bed Fusion (LPBF) Machine Design: A novel LPBF system, AZAR, with innovative features has been designed and built. The unit is equipped with a high performance printing enclosure with tightly-controlled atmosphere (i.e., O2 content regulation) for effective processing of reactive metals such as Al, Ti and Zr alloys. The unit will soon be equipped with a unique laser-based in-situ monitoring camera as well.

Advanced Aluminum Alloy Development: Together with our industrial partners, we are developing alloy compositions and processing routes for Al alloys in order to achieve superior mechanical performance and corrosion resistance in sheet products. Our current focus is on novel rare-earth (e.g., Ce and La) modification of 5000 (Al-Mg) and 6000 (Al-Mg-Si) series alloys with applications in aerospace, automotive and electronics sectors.

High Entropy Alloys (HEAs) for Extreme Environments: Together with several academic and industrial partners from around the globe, we are working on rapid alloy design (via LPBF of elemental powders) and bulk fabrication of innovative HEA chemistries for extreme environment applications, e.g., the next-generation fission and fusion reactors.

Friction Stri Welding/Processing (FSW/FSP): Together with several academic and industrial partners from around the globe, we are working on optimization and development of FSW/FSP of adavnaced aluminum alloys and aluminum-based composities for electrical vehicles (EV) applications (e.g., batteries).

Specialty Metal Powders for AM applications: We are actively working with our industrial partners for developing, characterization and LPBF-testing of AM metal powders with superior characteristics. In particular, these powders are custom-manufactured with controlled size distribution, exceptional sphericity, oxide-free internal microstructure and uniform chemical composition.

LPBF Process Design and Optimization: We are rigorously working on devising processing criteria for improved as-built properties in LPBF-produced components. My research team performs advanced microstructural and mechanical characterization on test coupons as well as on real-size components produced by our research partners.

Simulation of Solidification and Precipitation Phenomena: We work with academic collaborators utilizing advanced Phase-Field Crystal simulation methods to understand the mechanisms of phase transformation phenomena and microstructural development in relation to the processing parameters in a variety of metallurgical processes (e.g., LPBF, Casting & Age-Hardening Treatments).

Thermal FEM Modelling of LPBF process: A novel FEM model of the LPBF process is developed and currently under validation by my research team in order to realistically predict the temporal development of temperature, melt-pool morphology and residual stresses throughout the build process.

Undergraduate Courses

Graduate Courses

Research Teams

Additive Manufacturing

Alireza Jalali (PhD Student)

Pusong Wang (PhD Candidate)

Ashkan Alimehr (MASc Student)

Sara Bourque (Undergraduate Research Student)

Jacquie Groenewegen (Undergraduate Research Student)

Arash Nikniazi (Research Assistant)

Maryam Ghaferi (Visiting PhD Student)

Thin Strip Casting

Shengze Yin (Post-doctoral Fellow)

Hesam Pouraliakbar (PhD Candidate)

Mary Gallerneault (PhD Student)

Ali Jalili (MSc Student)

Advanced Aluminum Alloy Development

Mohsen Saboktakin Rizi (Post-doctoral Fellow)

Fatemeh Allahdadi (PhD Student)

Farideh Moghabeli (MSc Student)

Radin Moradi (MSc Student)

Alumni:

Shengze Yin (PhD Graduate, Alumni)

Adib Salandari Rabori (PhD Graduate, Alumni)

Qingshan Dong (Post-doctoral Fellow, Alumni)

Lin Zhu (Visiting PhD Student from Jilin University-China, Alumni)

Kellan MacDonald (Undergraduate Research Student, Alumni)

Nathan Jones (Undergraduate Research Student, Alumni)

Daniel Howells (Undergraduate Research Student, Alumni)

Zihao Zhuo (Undergraduate Research Student, Alumni)

Aiden Estabrooks (Undergraduate Research Student, Alumni)

Dr. Fallah’s research group welcomes applicants with strong background/interest in Materials Characterization and Analysis (Microstructure and Mechanical Properties), Solidification and Phase Transformation in Metals and Mechanical/Electrical Design & Control.